Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

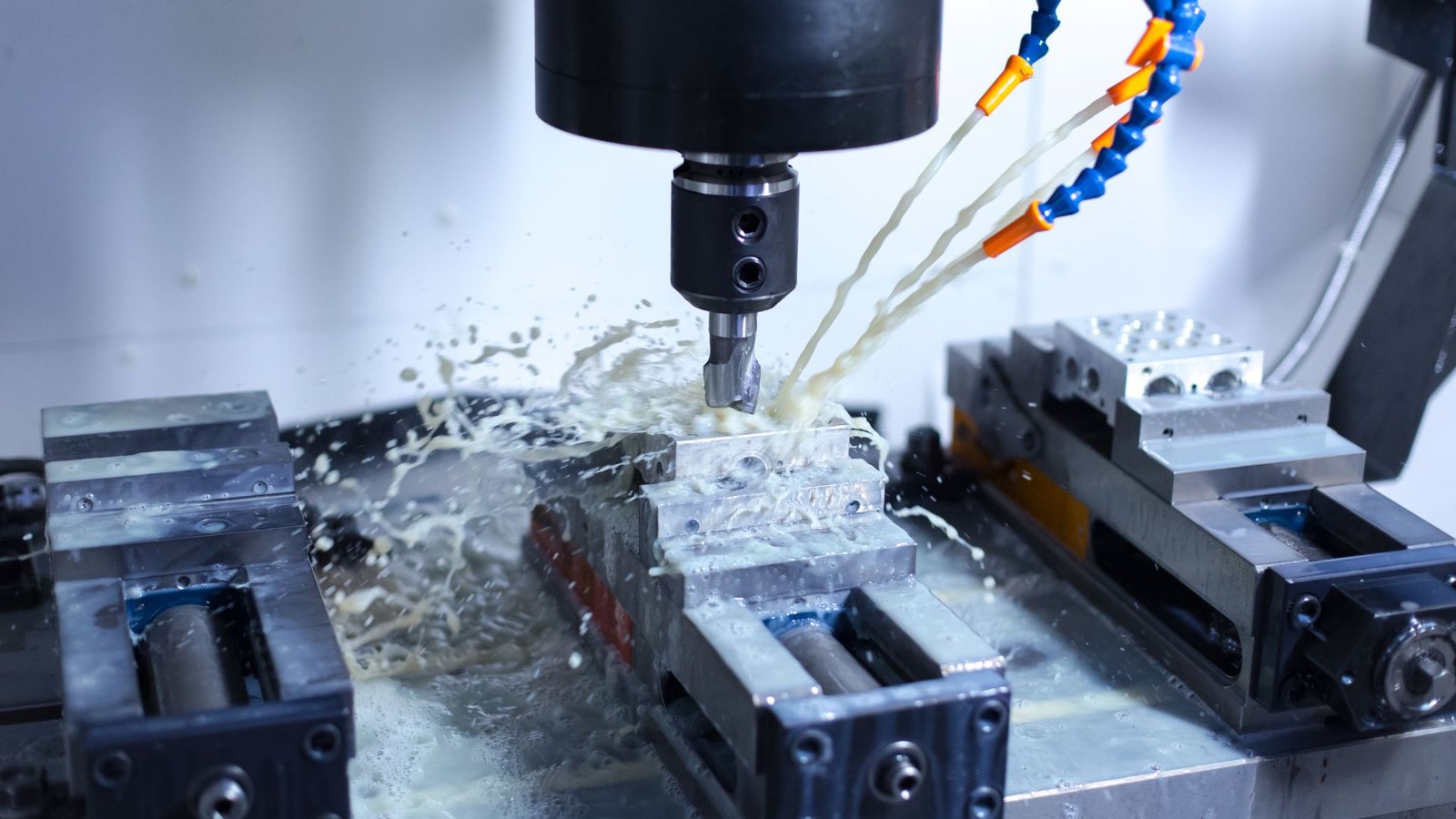

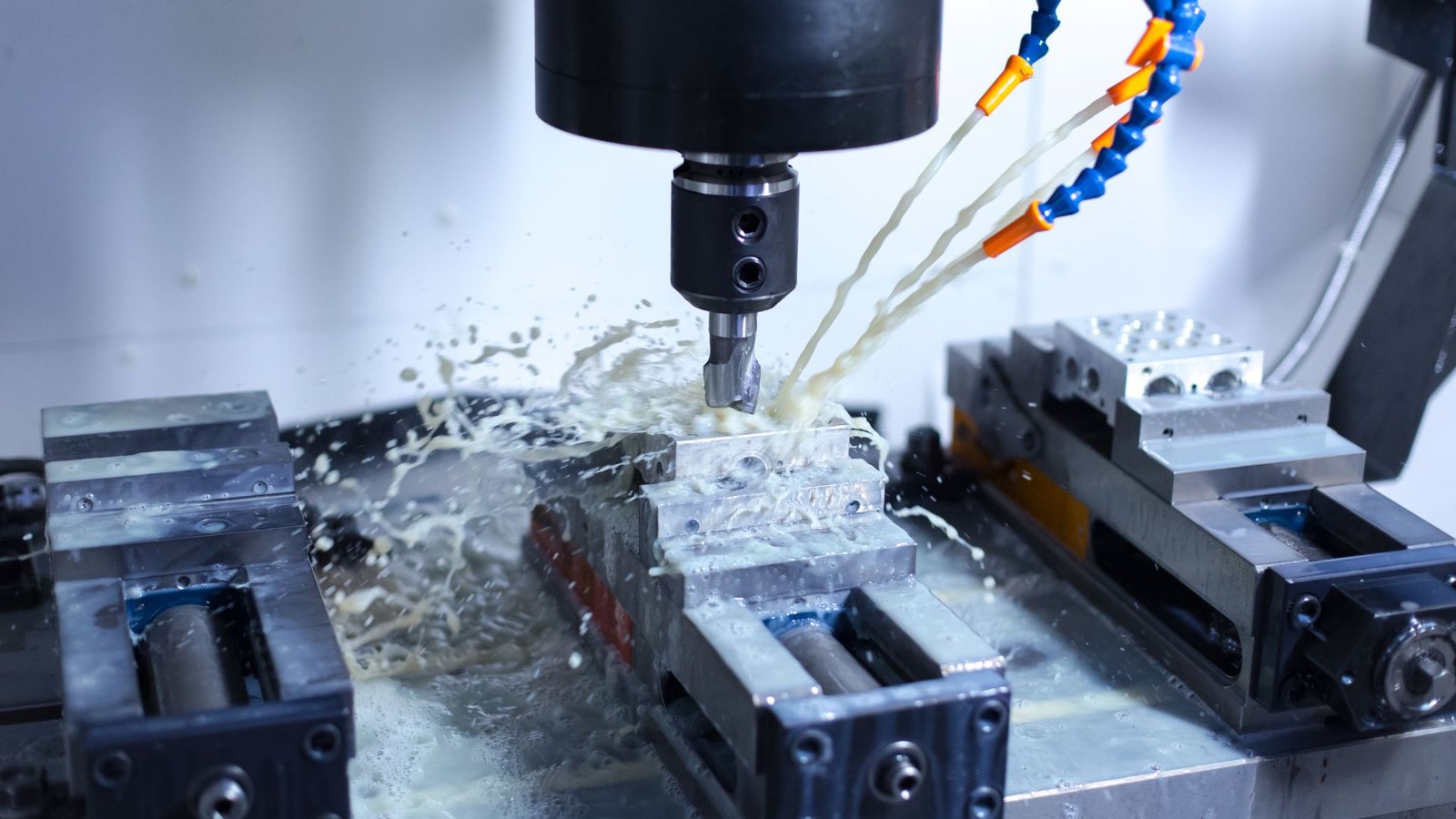

Client: CNC Machining Company

Sector: Precision Engineering (Medical & Aerospace Components)

Location: Hertfordshire

Challenge:

Despite using high-precision machinery, the client lacked insight into OEE (Overall Equipment Effectiveness) and could not justify recurring maintenance costs due to the absence of hard data.

Solution:

Results: